I want to preface this with a warning that I am not an electrical engineer, or an electrician. You should use this information as a guide to get started but do your own due diligence. Only those qualified should do work on your house electrical systems.

This all started thanksgiving this year. Our only snow of the season so far. I was hauling a Megabot suit across the country leaving my wife home alone. When we purchased our house, we had some clear signs of damage from freezing pipes. The previous owner did what could best be described as quarter assed prevention of them freezing again. The garage door was off it's tracks, heat tape had been taped to some pipes, and pink foam panels had been affixed to the ceiling to try and keep the pipes from freezing. All of this depended on having electricity.

The electricity went out. Libby went to stay at her sisters who had power and eat a thanksgiving dinner that couldn't be beat and didn't get up till the very next morning. I was on the road and could not help so I called up my friend Tyler who was eating dinner at his parents house. He was able to come and drain the water from our pipes and help us make sure we did not have our pipes blow again. My wife strongly urged that we come up with a better solution to power outages.

Since the heater did not give me enough information I needed to go to the instruction manual. I did not try and get down on the ground, so the information could have been on a panel that I did not see. I looked over the entire unit but it does not give me information on total draw so I will use an empirical estimate of 15 amps since that is the size of the circuit.

In the above chart, I have given an example of what this may look like. I am having a new service installed so I am going to have my load balanced then. What you do see in this chart is that my dryer and stove take a lot of electricity. In order to buy a 500 dollar generator instead of a 3,000 dollar generator you will have to make concessions and not use the stove and oven for the duration of the power outage. In the following chart you can see what my plan would be.

You will need to reduce power consumption until full power is restored or purchase a larger generator. The stove does not use full power when only a single burner is running so you can still cook a meal or heat some tea. If you have gas power stove and dryer, this is a non issue. A comparable burner is 1000 watts of power or about 8 amps.

Generators are usually rated by watt output. We will have to get our amp total back to watts with the simple WATTS=AMPS*VOLTS. Important note! Since some generators will be a 240 volt connection, it will draw from both sides at a maximum. 30Ax120V+12A*120V=5040W. This is what the number lead you to believe. In reality, we need to double the highest load side and use that for the power calculation. 30Ax120V+30A*120V=7200W So a 7200 watt generator would be needed to operate this at full capacity.

This all started thanksgiving this year. Our only snow of the season so far. I was hauling a Megabot suit across the country leaving my wife home alone. When we purchased our house, we had some clear signs of damage from freezing pipes. The previous owner did what could best be described as quarter assed prevention of them freezing again. The garage door was off it's tracks, heat tape had been taped to some pipes, and pink foam panels had been affixed to the ceiling to try and keep the pipes from freezing. All of this depended on having electricity.

The electricity went out. Libby went to stay at her sisters who had power and eat a thanksgiving dinner that couldn't be beat and didn't get up till the very next morning. I was on the road and could not help so I called up my friend Tyler who was eating dinner at his parents house. He was able to come and drain the water from our pipes and help us make sure we did not have our pipes blow again. My wife strongly urged that we come up with a better solution to power outages.

Step One: identify power needs.

How much power will you need to provide? This is a decision you will need make based on needs and wants as a trade off. Most importantly, how do you heat the house to keep pipes from freezing?Wood Stove

If you have wood stove you just need some wood and you are good to go. Anything beyond this will become luxury. To power this type of heater, you will need a large breakfast of eggs and bacon. You may have some air circulation fans that should be powered, but this will be very low on the power requirements.Electric Heat

This will be hard if not impossible to run off a portable generator. An 80,000 btu Electric heater requires approximately 25kw of power. This can be costly to run and is expensive equipment. You will likely save money over all by converting to natural gas. Check with your local utility for available rebates.Propane/Natural Gas/Wood Pellets

The heating systems use other fuel than electricity for a power source. This means that the electricity required is for circulation, venting of exhaust gas, and air handling. This is just a fraction of the required power and can easily be handled by a small generator.Calculating power needs.

Power needs are very easy to calculate. We will use watts as our power unit for this. Most pieces of equipment will have a label that explains the power requirements under maximum load. When motors turn on, they draw more energy. For anyone who does not have a moderate understanding of Ohms Law recommend that everyone go out and get Solar power for dummies. The concepts of power and energy are well laid out and will get you started with a self evaluation.

|

| My set up has a natural gas fired hot water heater and hydronic power source for baseboard heaters. |

|

| Lets look at what my heater requires for power. It has two 3 amp 120 volt pumps. The manual does not state input amperage or total wattage so I will need to do some more research. |

|

| The water heater was sitting next to it so I grabbed that info as well. |

I now have two of the three things I really care about. The last is the fridge. Since I don't really care that much, I again am going to assume 15 amps. If I actually care I would put a clamp meter on one of the hot wire to find out what the draw is. This can be deceiving. On start up many of these motors will draw up to twice the operating current of the item. If you are not comfortable splitting out wires, pick up a line splitter for safety. These two items can also be used when reducing power consumption within your house.

When looking at any electrical device, if they don't call out an amperage, then they will likely call out a wattage. For items that just give you a watt rating, the calculation is very simple. WATTS = VOLTS * AMPS. So on a 120 Volt line AMPS= WATTS/VOLTS so my 1200 watt microwave can be calculated 1200W/120V=10A This also shows the benefit of high efficiency items in the house. a 60 watt conventional light bulb is equivalent to an 8 watt LED bulb. Are you starting to see a theme here? Reducing energy consumption saves money every day on the electricity bill. Saving energy also saves money on what the generator system requires.

|

| A load center with no Breakers installed. |

Next I need to look at how the load is balanced. Residential electricity is split into two legs. It comes in with two lines that together have a 240 volt potential. The neutral wire has a 0 volt ground reference and will show each leg as 120 volts. What does this mean for you as a future generator operator? It means that if all of your vital where the breakers are installed. If all of the important circuits are on a single leg you will not be able to fully utilize your generator, or need to buy a larger generator than required. If this does not make sense to you, I recommend you contact a qualified electrician. If load balancing will help, this can be done when you install the transfer switch.

|

| A sample power chart. |

In the above chart, I have given an example of what this may look like. I am having a new service installed so I am going to have my load balanced then. What you do see in this chart is that my dryer and stove take a lot of electricity. In order to buy a 500 dollar generator instead of a 3,000 dollar generator you will have to make concessions and not use the stove and oven for the duration of the power outage. In the following chart you can see what my plan would be.

|

| Emergency power loading. |

Generators are usually rated by watt output. We will have to get our amp total back to watts with the simple WATTS=AMPS*VOLTS. Important note! Since some generators will be a 240 volt connection, it will draw from both sides at a maximum. 30Ax120V+12A*120V=5040W. This is what the number lead you to believe. In reality, we need to double the highest load side and use that for the power calculation. 30Ax120V+30A*120V=7200W So a 7200 watt generator would be needed to operate this at full capacity.

Step Two: Choose a generator

Many of these units will have two power rating, intermittent and continuous. For all of my reference, assume I am talking about continuous power. When looking at stats talk in continuous power output and make sure any sales people you talk to provide information in this format.

Inverter: 200-400$

My first plan which was possible was to get an inverter. You can get a high duty cycle model that can output 600 watts continuous for reasonable money. This can run off of a car battery with the car running for a period of time. It is a solution that is a compromise on many levels, thee car is not meant to sit and idle for long periods and the electrical system is not designed for constant draw high current like this. However, if the choice is to risk damaging your alternator, or freezing the pipes, it may be worth it. This can also be a stop gap if the supply of generators has dried up in the area and the power is still out. You may damage your car with this method for long periods of use. I recommend borrowing your mother in laws car for this reason. Shut off headlights and AC for best results.Small quiet portable generator: 500- 1500$

I have two recommendations for small quiet generators. They have a few benefits I would like to go over first. Quiet means they are less likely to annoy your neighbors while running all night in your warm house as they shiver in their fortress of poor preparation. It is also light and easy to move around. A down side is that it is easy to steal. The Ryobi 2200 is a great unit for the money. It is a knock off of the Honda EU2000ia unit that is a favorite of Burning man attendees. It is small quiet and aesthetically pleasing. Honda also makes a Parallel cable that allows two units to be used in concert. This puts the entire kit for a 4000 watt generator to 3250$. It is quiet and a reliable system. It is also a nice take along system for camping or working on the cabin so it may have some non financial benefits. Ryobi makes a similar kit ST-PKIT2000 that has constantly varying stock. If you plan to go this route, purchase one when you see it.

Medium Portable Generator 300-2500$

You can start with the Harbor Freight special for 200 and it goes up from there. If you don't buy a good generator in the first place, you will still pay for an expensive unit in maintinance and still not have it in the end. I would spend a few more dollars and buy something that has some grunt. The more reputable manufacturers will be honest with the numbers. I like Generac as a brand. They have decent support and and a large distribution channel. Do some research before hand and make sure that once you buy the generator, someone local can do warranty work as well as maintenance within a reasonable driving distance. I like a good 7500 watt system. When you buy it, spend the extra few dollars to buy a wheel kit and a cover. this thing will spend most of it's life in a corner doing nothing. these can weigh 100-300 pounds so get a buddy to help you lift it. Portable generators can give you up to 20,000 watts of power available. Once you get to this level, connecting and disconnecting from the household power becomes a problem. 12,000 continuous watts is about the upper limit of what you want to connect and disconnect from your home.

Permanently installed generator 3500$ and up plus instalation

You have PMV11 blades on all of your hand planes you keep in a climate controlled cabinet with back lighting. You don't want an extra step when the power goes out to get seamless transfer to the Independent republic of my house. These and many other reasons exist that you want or need to have power. Built in generators have very few downsides. The biggest one is cost. The initial cost is going to be much higher than the equivalent portable unit. Installation cost will be slightly higher for a manual transfer switch vs a bit more for an automatic. Cost will very by application. For greater power than 12000 watts this is the only reasonable off the shelf option. Fuel will often be Propane or natural gas. If you have a propane tank for heat, this will be a simple choice. If you have natural gas, you can risk loosing pressure which rarely happens but can during extreme winter power loss situations. Propane will give you the best stand alone solution.

Step three: Getting power into the house

Important note! When you connect a generator to your house it needs to be disconnected from the grid. Linemen work on the lines in a power outage with an expectation that they are off. If you turn on your generator after they have checked for power, you can kill them. the power you are putting into the line is only 240 volts, but it comes down a step down transformer. When back fed, this ups the voltage to upwards of 1000 volts. The reason for an interlock is to physically prevent back feeding of the system.

|

| This is how you kill people. |

Double make cords are known as widow makers for a reason. They can come out of a socket and leave a live 120 volt source (or 240 if you are using a larger plug) out and in the open for killing children and pets. I am giving a few options of how to get power into your house.

Oh shoot, it is a snow storm and we are not at all ready: 0$ and up

In the middle of the storm, you have somehow gotten a generator. Unfortunately you did not do any preparation and can't figure out how to plug the generator into the heater. Somewhere around your heater is an electrical box. Once you find it, go to Facebook on your phone and beg your friends who may be an electrician or know of one who can come to your house and fix this problem for the low cost of a boat payment. Do not try and do this yourself unless you completely understand how everything is wired and the experience to safely change over the circuit. If you do decide that you know what you are doing, get into that box and separate the connection after you have shut the circuit off at the box. Cap off the unused supply with wire nuts connect an adequate power cord that can then be connected to an extension cord and reach the generator. This is a pretty simple set up and is easy to reverse. Once the storm is over, do it properly. Every step you take think about potentials. Ask yourself will this put anyone at risk? When the power comes back on, what will happen? Just so it is said 7 times, if you don't know what you are doing, don't mess with this. My house burned down last year due to poor existing wiring.

One circuit for the heater: 100$ + Installation

Reliance makes a nice transfer switch that will switch over a single circuit. All in, you are looking at about 300 dollars installed by a licensed electrician. This can be done easily by a competent DIY person. You need some amount of wire to make the junction so you should locate this box near another junction box that exists. If the breaker panel has space, having the shutoff near the breaker panel makes for a simpler operation of the transfer. ProTip have a flashlight near the breaker box that is ready to go during a power outage. I recommend a headlamp style led light. It keeps both of your hands free for trying to start the generator. This is also great for inverter installs that are going to be 1500 watts or less power.

Sister Box: 250-800$ + Installation

Reliance makes another great product that allows you to switch over only a few select circuits. This is for a transfer switch that runs in parallel for 2-10 circuits. You can switch things off individually based on needs. This is a great option if you have a 200 amp modern service installed. If you have limited power and members of your household who can't consciously change behaviors based on power consumption. These will often be rated at 7500 watts. This is due to the limitations of a 30 amp 240 volt connection. It is the most common connector on generators for RV's and has trickled down into backup generators where the two markets cross over.

Load center transfer switch: 500$ + installation

Load centers with mechanical interlocks. This means that you can't physically back feed the line and put linemen at risk. You will find two styles of manual transfers. they will be designated with fractions. The previously linked load center is labelled 40/40 which means that in both standard and generator modes, all circuits get power. Critical load transfer switches have a limited amount of "utility circuits" that function during generator power and "standby circuits" that are only energized while connected to the grid. Many of these boxes come ready to have an automatic transfer switch installed. If you have any thought about doing this in the future, choose a box that can be retrofitted during the initial installation. In order to install this, you will be dealing with the main service coming from the road. This will not have an easily accessible shut off so bringing in a pro is a good investment. During this step, talk to your electrician about load balancing. With the clamp meter and a friend, you can map out what each circuit supplies and how much current is required. Giving this information to your electrician ahead of time will make sure they know what you want.

This is the option I chose for my installation. The number one reason I chose this was fear. Earlier this year, my wife and I lived through a fire. It was started by existing electrical work that shorted.

Additional contributing reasons for the change:

- In our new house, we have an old 100 amp service.

- Some of the breakers need to be replaced. The breakers are old and hard to find a replacement for.

- I want to install a cnc mill and a welder in the garage and this will require more power.

- We run a very efficient house so a small amount of power will run the whole house on the generator.

- The cost of a service upgrade was 1800 alone. The cost of a 30 amp generator hook up was 800 installed. Together, I get 400 dollars off and everything done in one day.

- The new service will also give me smart grid features so I can better monitor our energy uses.

Automatic transfer switch: 500-1000$ + Installation

I have no experience and have done zero research on theses. If this is what the route you are going, you should contact someone local who specializes in the systems. I would also recommend choosing a single source solution. if you buy a generac generator, buy a generac automatic transfer switch. They will integrate better and dealing with service and warranty is simpler. by integrating two different manufacturers, they will both blame each other when a problem does come up. This is also the only reasonable option for 12,000 watt and greater continuous generators.

Step four: Plugin it in

Now that you have a thing wired, you need to connect it to the generator. If you have hardwired it, you can skip this step.

Extension cord: 25-300$

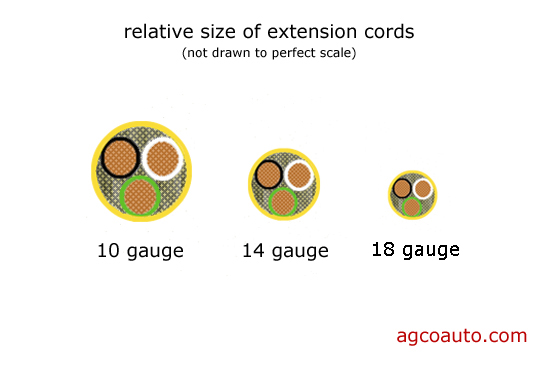

Length and current will determine how large a wire diameter you will need. You have already spent well north of 500$ at this point so don't skimp on the cord. Get a dedicated cord that sits with the generator. It is not an extension cord, it is part of the generator. It should be stored in a pouch attached to the generator coiled neatly. For 15 amps, get 12 gauge up to 100 feet. For 20 amps get 10 gauge up to 100 feet. For 30 amps ,get 10 gauge up to 65 feet. For 50 amps up to 50 feet get 6 gauge. You may need thicker cable for longer distances. This is a jumping off point that will get you a safe cord. Please do research in what cord you plan to link the generator to your house. Get a bright color if possible. This will stick out when you are trying to find it in the snow. It also may help you avoid cutting the cord in half with a snow blower. (ask me how I know)

Standard outlets: Nema 5-15 and 5-20

This is the same outlet you will use almost everywhere in your house and at work. You will need an extension cord of some kind to connect them. This should be a sturdy weather sealed cord ideally with lighted ends at each side. This will help when it comes time to trouble shoot operation. Depending on your amperage this may all that is needed.

30 amp Twist lock 14-30

If you are doing 30 amp 240, this is the only choice in my opinion. The 14-30 twistlock is widely used and available in many different configurations. Twistlocks give a positive engagement and will stay secure in the generator and power inlet on the house. Buy a good brand that is UL listed as a product. When it comes time to enter the house, weather proof assemblies are available.

50 amp Twistlock

I am unsure of what the actual nema code on this is. When you get up to this size, you will likely be building a custom cord. The female plug assemblies have three prongs and the ground is an outside contact of the connector. They have a mechanical lock beyond just the brings for a secure connection.

The power inlet has a male plug version of this. It will transfer a large amount of mechanical force so it should be securely fastened to a stud with heavy lags or deck screws.

On the generator side, often you will find this straight blade plug set.

Minimum rated components

When selecting the components for the cord, keep in mind that you need over current devices. whatever parts you put between the generator and your heater need to be rated for the maximum allowable amperage. For instance, if you know the heater only draws 1 amp, but the main breaker is rated for 50 amps, everything up until the heater needs to be rated for 50 amps.

I have ended up with a 50 amp power inlet twist lock, and then a 10 gauge 30 foot cord to the 30 amp twistlock. This will allow me to upgrade to a higher power generator in the future.

Step five: Kick the tires and light some fires

Here is a list of tips for operation of the generator.

- If the generator is heavy, get a wheel kit, or build one. On rough terrain, bigger casters are better.

- Use 93 octane fuel. It will make starting easier.

- Put in fuel stabilizer whenever fuel is stored in the generator.

- Make sure the generator starts up around September. You don't want to find out about needed repair work during the power outage.

- Have spare oil. Use synthetic detergent free.

- Turn your spare gas. Put a little manila hang tag with purchase date written in pencil or grease pen. Ink pens will bleed from the fuel. Keep about a gallon in the generator, the rest keep in a fuel jug. Once every few months, dump it in your cars tank and refill the 5 gallon container.

- Fuel has a shelf life when it has all of the additives that are now required.

- The new CARB complaint tanks are a pain to work with. If you have older jugs, hold onto them.

- When the power is out, people can get desperate. If they need a generator, they may take yours. The first line of defense is to stash it away in the back yard or side where it is not so easy to see from the street. Once you have planned out where it will be, figure out a way to lock it to your house. Backing your car up and chaining it to a subframe member works great in a pinch until you forget and drive away dragging it with you. A cable lock with an anchor point should be planned.

- Think about how you will get the generator from the storage to service. If it is burred in the back of the garage, you will be kicking yourself while digging it out with a flashlight.

- Test your setup and practice hooking it up. Teach others in the house to operate it as well. They may need to refuel and restart it.

- Have a spare spark plug.

- Have a can of starting fluid handy.

- When hiring an electrician, get references from friends and family. The reference should not be "Hire my boyfriend, he is a great electrician". It should be "I hired Sue to do this job and she was a good communicator, showed up when she said she would. She completed the job to my satisfaction and I would recommend her to anyone who needs work done."

- If you can't get a reference, try and find an electrician who has been at it for a while. Angies List is a good source for this.

- Doing business with friends and family can be stressful. Expectations often are not made clear on one or both sides prior to the work that needs to be done.

- The electrician pays less than you for materials. He will charge you the same price, or more than you would pay at home depot. He is not screwing you, this is part of the business model. If you buy your own supplies, the electrician likely won't cover them with a guarantee. And may even increase the cost of the job.

- An electrician is like a doctor. You pay them for their experience, not so they can recite the nema code book. When you explain your goals, listen to the feedback they give you.

- this person is going to be in your house, you should feel comfortable with them to be in your house with you.

- They should pull permits for you and show you a license. Go online and verify it is a valid license.

- If your neighbors do not have a generator, figure out what it would take to tap off a little bit of power.

Be safe everyone!